The waste gas generated during the production of phosphorus chemical industry mainly includes carbon monoxide, sulfur dioxide, carbon dioxide, hydrogen fluoride, silicon tetrafluoride, phosphine, hydrogen sulfide, etc., along with some dust. Carbon monoxide (CO) is a colorless, odorless, flammable and toxic gas, and yellow phosphorus tail gas is the main source of CO. Therefore, it is an urgent and critical moment to prevent global warming caused by carbon dioxide (CO?) gas. Sulfur dioxide (SO?) is a colorless, slightly odorous and suffocating gas, and also one of the main substances causing air pollution.

Weng'an is hailed as the "Phosphorus Warehouse of Asia" due to its abundant phosphate rock resources. Endowed with rich mineral resources to fuel economic development, Weng'an County has always adhered to the two bottom lines of development and ecology to promote the transformation and upgrading of the phosphorus chemical industry. It has continuously taken new-type industrialization as the main direction for the high-quality economic development of Weng'an, firmly established and practiced the concept that "lucid waters and lush mountains are invaluable assets", and unswervingly taken the path of industrial ecologization and ecological industrialization. It is against this background that Weimei Environmental Protection has the opportunity to participate in a series of production technology upgrading and transformation projects of Longma Phosphorus Industry.

Clean Production Technology Renovation Project of Yellow Phosphorus of Weng'an Longma Phosphorus Industry Co., Ltd.

The gas handling capacity of each of the two wet electrostatic precipitators is 250,000 m³/h, and the flue gas temperature is below 85℃. The inlet and outlet of the demister are arranged in a bottom-in and top-out mode. After the equipment is constructed, the weight of the steel frame, access ladder and platform of a single unit is about 98 tons, the weight of internal components and insulation system is about 102 tons, and the total weight of a single unit is about 200 tons (excluding the inlet and outlet flues).

Project of Yellow Phosphorus Waste Gas Treatment with Wet Electrostatic Precipitator for 250,000 m³/h Gas Volume in Guizhou

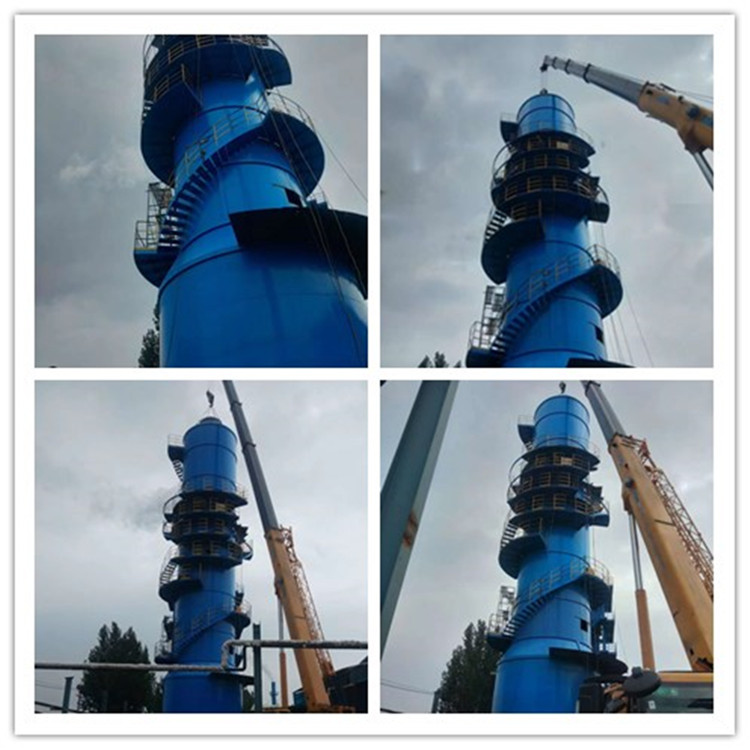

Wet Electrostatic Precipitator for Deep Desulfurization of Terminal Flue Gas from Yellow Phosphorus Tail Gas with 500,000 m³/h Gas Volume

Longma Phosphorus Industry carries out deep desulfurization treatment on terminal flue gas. The gas volume of the flue gas undergoing desulfurization renovation is 500,000 m³/h, with the required outlet concentration of sulfur dioxide less than 100 mg/Nm³ and particulate matter less than 75 mg/Nm³. Medium of the desulfurized flue gas: the flue gas is generated from the combustion of yellow phosphorus tail gas (mainly CO), containing highly corrosive media such as sulfur, phosphorus, arsenic and fluorine. The temperature of flue gas entering the desulfurization tower is ≤ 120℃.

Project of Wet Electrostatic Precipitator for Wet Desulfurization of Terminal Flue Gas

The wet electrostatic precipitator on the left has been operating stably for more than two years, while the one on the right is the newly commissioned wet electrostatic precipitator for deep desulfurization of terminal flue gas from yellow phosphorus tail gas with 500,000 m³/h gas volume.

The entire wet electrostatic precipitator system is equipped with a PLC automatic control system, which automatically controls spraying and cleaning. Meanwhile, the PLC system reserves communication interfaces, and all data are uploaded to the DCS system, enabling automatic control from the central control room to the DCS system. The flue gas treated by the wet electrostatic demister is the desulfurized flue gas mixed with water vapor, containing highly corrosive media such as sulfur, phosphorus, arsenic and fluorine. The operating temperature is ≤ 90℃, and the operating pressure is ≤ 5,000 KPa.

Clean Production Technology Renovation Project of Yellow Phosphorus of Weng'an Longma Phosphorus Industry Co., Ltd.

Baghouse Dust Collector for the Flue Gas Pre-treatment Unit of the 100 t/h High-temperature & High-pressure Gas-fired Boiler (540℃, 9.8 MPa) Fueled by Yellow Phosphorus Tail Gas

This unit adopts sodium carbonate (Na?CO?) as the flue gas treatment agent, and employs a baghouse dust collector for mist removal. The flue gas pre-treatment unit consists of four parts: a raw material silo, a feeding system, a mixing and drying system, and a baghouse mist eliminator. The flue gas in this project has high contents of sulfur, phosphorus and other acidic substances, so the flue gas pre-treatment unit must fully consider the corrosion caused by sulfur, phosphorus and other acidic substances. All flues in the flue gas pre-treatment unit are made of materials not lower than 2205 duplex stainless steel and 316L stainless steel.

Stable Operation of the Baghouse Dust Collector (1,760 Bags) for the Comprehensive Utilization & Pre-treatment Unit of Yellow Phosphorus Tail Gas

The flue gas pre-treatment unit is composed of four parts: a raw material silo, a feeding system, a mixing and drying system, and a baghouse dust collector .

The yellow phosphorus tail gas is treated by a coal gas purification filter and then enters a gas holder. After being purified by a desulfurization device, it is fed into the 100 t/h boiler of the yellow phosphorus tail gas power generation system for combustion. The exhaust gas generated by combustion is treated through the process of flue gas pre-treatment unit + baghouse dust collector + “wet desulfurization + wet electrostatic precipitator”. SO?, NO? and particulate matter can meet the emission standards, and are finally discharged through the existing 50-meter-high exhaust stack.

+86-18633235200

+86-18633235200