Stepping into the garden-style green factory of the Guizhou customer, four sets of wet electrostatic precipitator equipment designed and manufactured by Hebei Weimei Environmental Protection for phosphochemical tail gas treatment are operating stably here.

There are four sets of wet electrostatic precipitator equipment for phosphorus chemical tail gas treatment. On the left are two electrostatic precipitator with a capacity of 250,000 m ³ /h and a gas volume of 2. On the right is one wet electrostatic precipitator with a capacity of 500,000 m ³ /h and a desulfurization system. On the south is one electrostatic precipitator with a capacity of 50,000 m ³ /h.

500,000 m ³ /h gas volume:

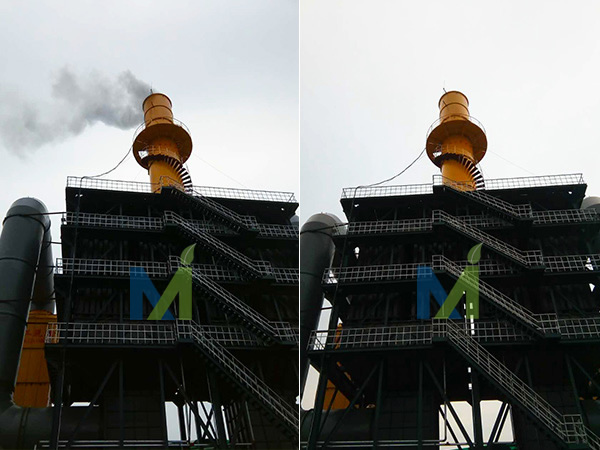

A certain phosphorus industry company in Guizhou Province carried out deep desulfurization treatment on the terminal flue gas. The desulfurization transformation flue gas volume was 500,000 m ³ /h, with the outlet concentration required to be less than 100mg/Nm3, and the particulate matter less than 75mg/Nm3. The wet electrostatic demister treated the flue gas into desulfurized flue gas and water vapor. The flue gas contained strong corrosive media such as sulfur, phosphorus, arsenic, and fluorine. The working humidity is below 90 degrees Celsius and the working pressure is within 5000KPa.

250,000 m ³ /h gas volume:

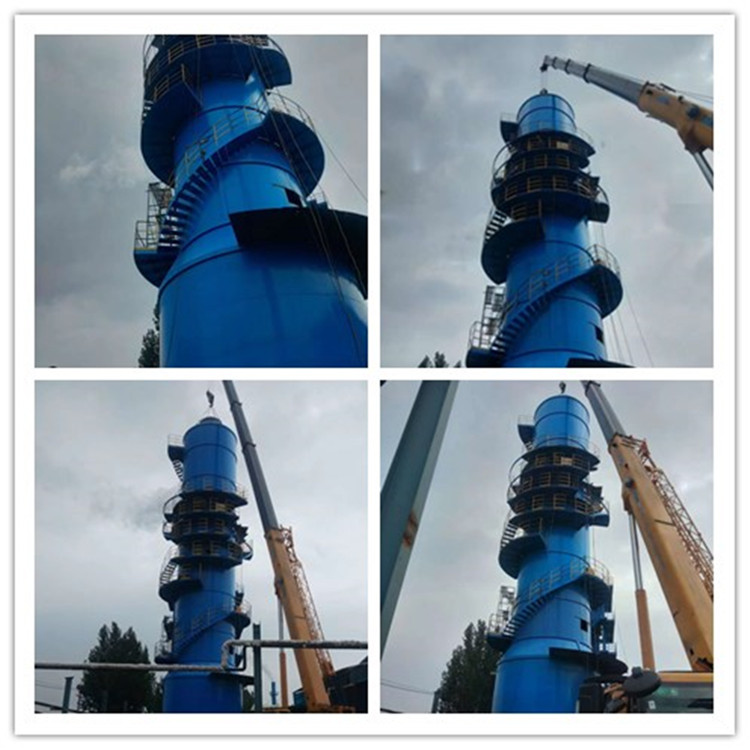

Phase II Project of Technical Transformation for Clean Production of Yellow Phosphorus. The gas handling capacity of this electric demister is 250,000 m³/h, with the flue gas temperature below 85°C. The air inlet and outlet of the demister are arranged in a bottom-in and top-out manner. After the equipment is completed, the weight of the steel frame ladder platform of a single unit is approximately 98 tons, the weight of internal components and insulation system of the equipment is approximately 102 tons, and the total weight of a single unit is approximately 200 tons (excluding the inlet and outlet flues).

+86-18633235200

+86-18633235200